ADVANTAGES OF CERAMIC COATINGS

A ceramic coating utilizes high-tech materials to create strong chemical bonds on your paintwork. Its thickness derives from sub-micron scale to a few microns. Cured film thickness of a ceramic coating is 6-10 times thinner than conventional top coats / finishes found on a passenger car. Despite its low thickness, a ceramic coating generally has high hardness. This value is two times higher than a top coat indeed.

DulvapTM nano coatings protect your paintwork against harmful environmental conditions, minor scratches and even can prevent stone chips. Minimizing dirt adhesion on coated panels result in easy-to-clean properties. It helps you to save time and money as well as avoiding the waste of our water. Common features of our nano coating products for paint protection are listed below:

![]() High Contact Angle

High Contact Angle![]() UV Protection

UV Protection![]() High Hardness

High Hardness

![]() Low Resistance to Slip

Low Resistance to Slip![]() Chemical Resistance

Chemical Resistance![]() Stone Chip Resistance

Stone Chip Resistance

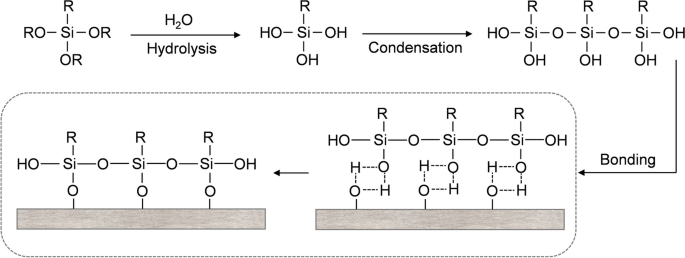

BONDING MECHANISM OF A NANO-CERAMIC COATING

A ceramic coating is applied onto finish of a car paint as a protection layer. Differing from the conventional macro coatings and polymeric sealants, they adhere to any surface at molecular level.

As being spread by an applicator, reaction between chemicals and moisture in air takes place immediately thus establishing a covalent bonding network. Basically, application of a ceramic coating is completed by wiping off the excessive part via a dedicated microfiber cloth.

Full curing of a ceramic coating is generally completed in a week at most. After the curing period, coated surface becomes resistant to environmental conditions.

APPLICATION HINTS & TIPS

Any surface should be free of dust and chemical residue prior to application of a ceramic coating. Depending on the physical condition of surface to be coated, multiple step compounding/polishing and decontamination may be required. Using chemicals free of silicone is a useful way to prevent potential residues left. Residues on surface may block the bonding between the coating and car paint finish.

- Read the instructions carefully before applying a ceramic coating.

- Choose an area without direct sunlight exposure and dust.

- Prepare the surface accordingly: Chemical Decontamination > Polishing > Washing > Removal of Residue with Alcohol Containing Cleaner

- Apply ceramic coating according to instructions. Do not allow high spots.

- Keep the coated surfaces away from dust, water and direct sun.

COATING MAINTENANCE

Car washing procedure and products used for exterior cleaning are important for protected surfaces. A careful detailing approach helps to get long lasting of a ceramic coating. Hence, liquid repellent and chemical durability features are retained further.

Using a dedicated pH-neutral car wash shampoo is an essential part of the exterior cleaning. Two-bucket method will eliminate the risk of scratching paintwork when using a wash mitt. A clean drying towel with high absorbency can be used for drying. Additionally, good quality towels enable scratch-free fast drying in ease.

Fallout particles, tar, glue and traffic film may stick on coated panels in time. In that case use of chemical products compatible with ceramic coatings becomes necessary. Suitable products remove contamination gently off the coated panels.

Prepare

Get rid of any residue left from polishing and decontamination before protecting your paint by a ceramic coating.

Apply

Protect your paintwork with a DulvapTM ceramic coating and keep your vehicle as brand new for years.